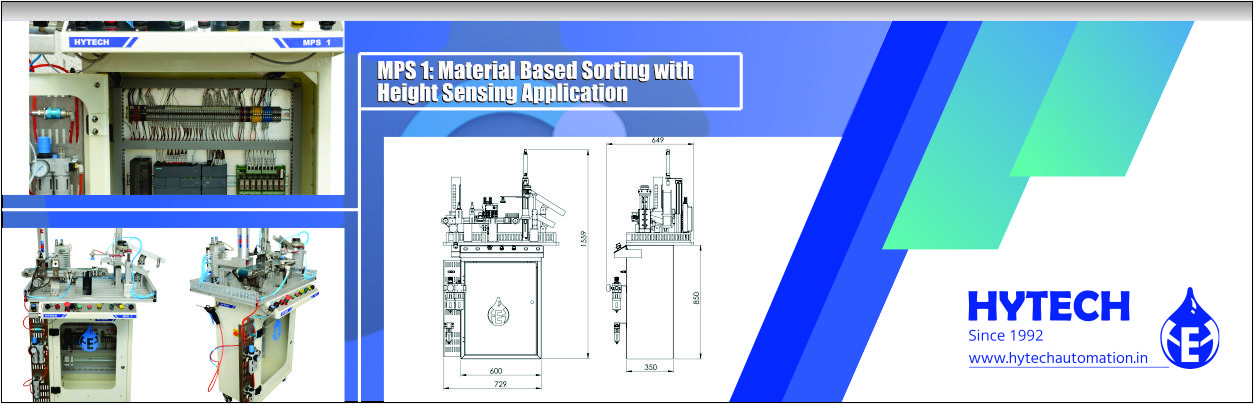

This is the first station of Hytech MPS system which is equipped with automatic loading tube. It can be connected to MPS 2.

Basic operational concept of this MPS is material based sorting along with Height sensing application. There are two separate provisions for rejections in this MPS. First rejection arrangement is mounted on the conveyor. Participants can select the job based on material (MS / SS / PU) to process further.

Height based sensing is again a rejection mechanism. Students can select the height of the job which will be processed to next station. In case if there is no MPS 2, participants can sort the jobs based on their heights.

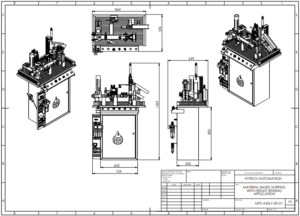

| MPS Station 1: | Material Based Sorting / Height Based Sorting with Auto Loading |

| Sr No | Description |

| 1 | Loader Tube 55mm ID |

| 2 | Push Cylinder, Guided |

| 3 | Sensor Mounting Bracket (Conveyor) M18 x 2 |

| M18 Capacitive Sensor | |

| M18 Inductive Sensor | |

| 4 | Height Sensing Unit |

| Square Cylinder 12 x 100 | |

| 5 | Conveyor 70 x 500mm |

| 6 | Rotary Rejection Module |

| Festo Vane Motor | |

| Rejection Slide | |

| 7 | Stopper Cylinder, Guided |

| 8 | Horizontal transfer station |

| Rodless Cylinder, 25 x 250 | |

| Mounting Plate for 40mm workpiece | |

| Push Cylinder | |

| 9 | Vertical transfer station |

| Rodless Cylinder, 25 x 250 | |

| Mounting Plate for 40mm workpiece | |

| Push Cylinder | |

| 10 | Rejection Push Cylinder |

| Rejection Push Cylinder | |

| 11 | Connecting Slide |

| 12 | Festo Valve Bank, 10 5/2 DA Solenoid Valves, 1/4 |

| 13 | Festo Pressure Switch |

| 14 | Festo Air Filter |

| 15 | FESTO FRL UNIT |

| 16 | Control Panel with Operation Module |

| 17 | Mounting plate of 22.5 mm thick aluminum extrusions with working dimensions of 820 x 540mm |

| 18 | Siemens S7 1200 PLC (S7 1215C) |

| 19 | HMI Connection Port with SCADA |

What can be achieved with MPS 1:

- Material based sensing

- Height based sensing

- Acceptance and rejection based on user preference

- Introduction to rotary pick and place unit

- Operation of auto loader

- Operation of rod less cylinder